Transforming Corporate Standards – Part 1: Why Data, Not Documents, Is the New Best Practice

Introduction

Problem: You’ve modernized tools, optimized workflows, and embraced digital transformation to reduce risk and remain competitive—except in one critical area: corporate standards. Despite their importance, corporate standards remain buried in bloated documents and outdated systems, restricting efficiency and progress for your organization.

Opportunity: Corporate standards management is outdated. Standards are stored as static Word or PDF files in shared folders or legacy systems, then compiled into large, hard-to-use work packages. Even when third-party systems are adopted, the reliance on document-based formats creates friction and inefficiencies throughout execution, from design to operations.

Solution: We introduce BechtPractices, an advanced platform designed to manage engineering requirements the way they should be—at the requirement level. BechtPractices achieves this improved granularity using a requirements database management system (RDMS).

What’s Next: This foundational post sets the stage for an eight-part blog series that explores how our BechtPractices approach improves content access, management, and efficiency throughout your organization.

In this article, the term corporate standards refers to the following collections, all of which can be improved with the BechtPractices system:

- Engineering Practices

- Process Design & Technology Practices

- Mechanical Integrity Practices

- Maintenance & TAR Work Procedures

- Corporate Policies

Why the Old Way Isn’t Working

Whether your organization uses centrally managed content, best practices from organizations like Process Industry Practices (PIP) or International Association of Oil and Gas Producers (IOGP) Joint Industry Project (JIP) JIP 33, licensed third-party systems, legacy owner and project-specific practices, or a hybrid solution, you’ve likely experienced common frustrations such as:

- Outdated or bloated documents that make it difficult to find relevant information

- Conflicting requirements that delay capital projects and increase rework

- Inconsistent interpretations of standards that affect quality, safety, and compliance

- Overly generic procedures that don’t reflect site-specific needs or real-world tasks

- Hard-to-use systems that burden subject matter experts (SMEs) and administrators with added work

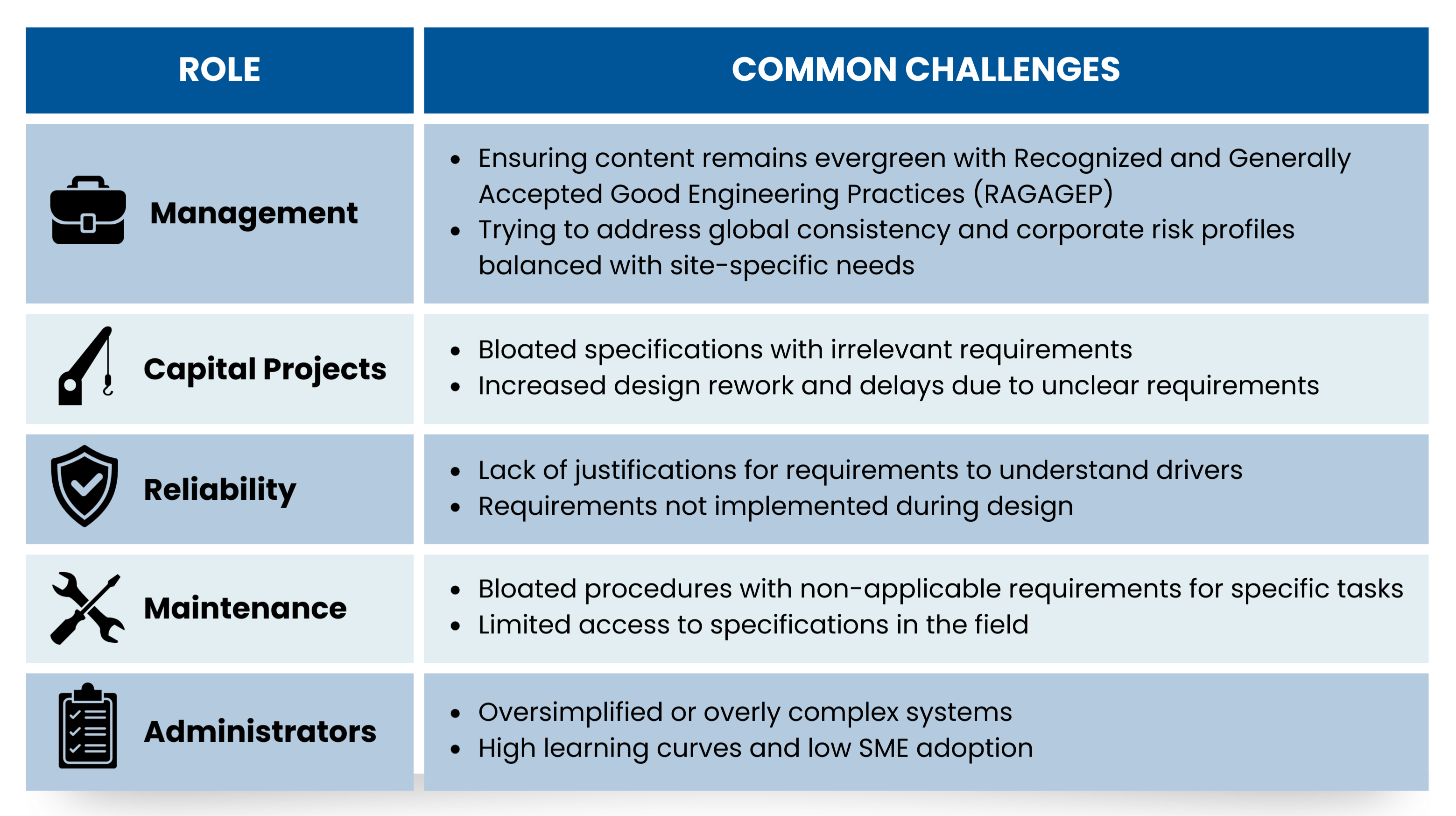

These problems affect every role in the organization:

Why Existing Solutions Fall Short

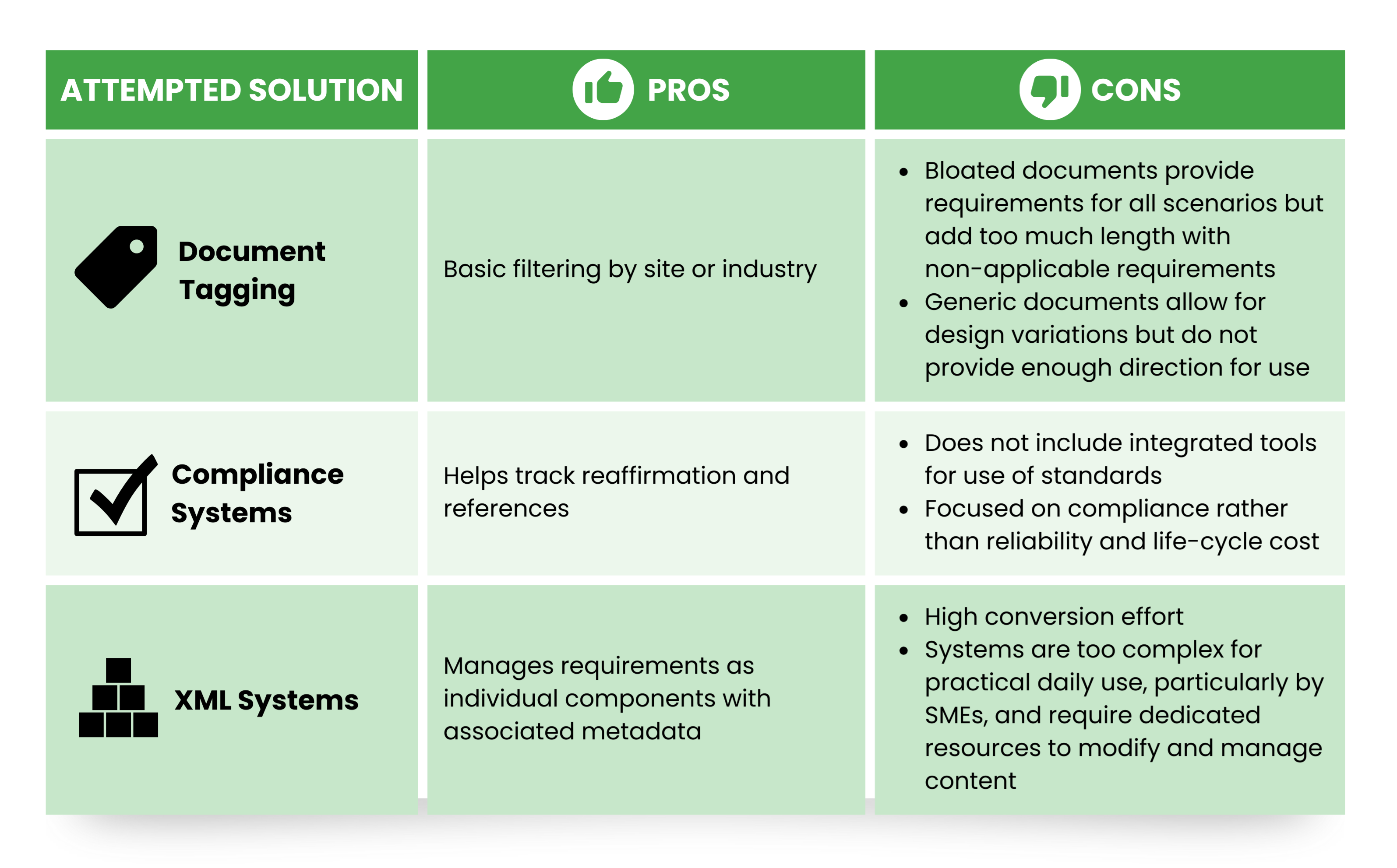

Several strategies have been attempted to improve standards management, but each has limitations:

These systems often solve one problem while making others worse, especially for engineers and end users.

BechtPractices: A Requirement-Level Solution

BechtPractices changes the game by improving the organizational foundation to manage standards at the requirement level in an RDMS.

For more information on RDMSs and the industry transition to digitalization of technical requirements, we recommend reviewing IOGP’s 2021 white paper, Digitalization of Technical Requirements. Simply put, an RDMS converts and stores each requirement as a row in a database. This architectural data organization allows for:

- On-demand filtering to show only relevant content based on project, location, or equipment

- Metadata tagging for better clarity, context, and knowledge transfer

- Advanced tools like requirement-level version compare, integrated approval workflows, improved AI-enhanced search, and advanced content layering for seamless integration of overlay content and deviations

- Improved functionality with integrated overlays to use with PIP, IOGP JIP 33, or other licensed content

- Ease of use through a familiar, Word-like interface tailored for engineers, not just administrators

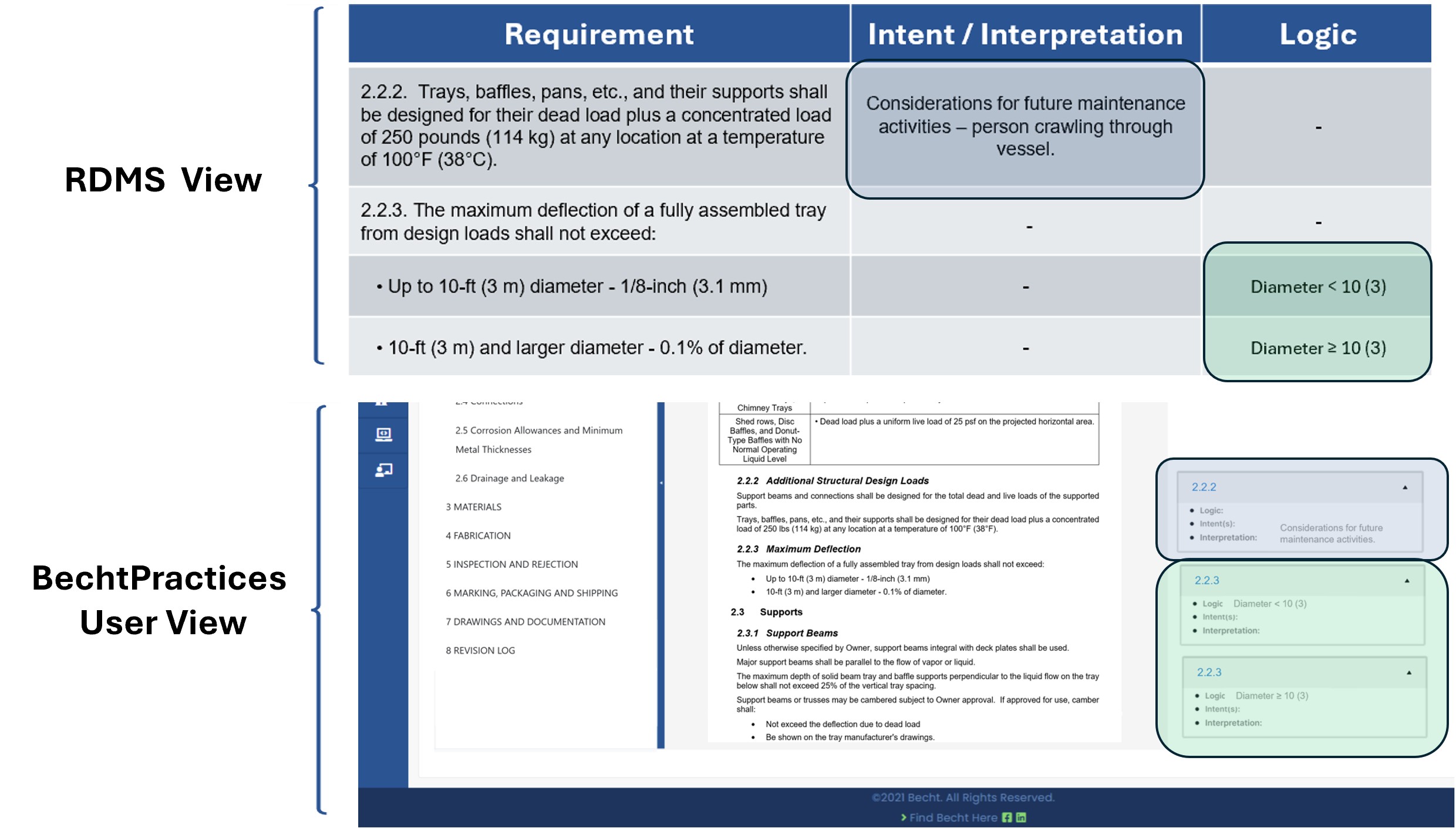

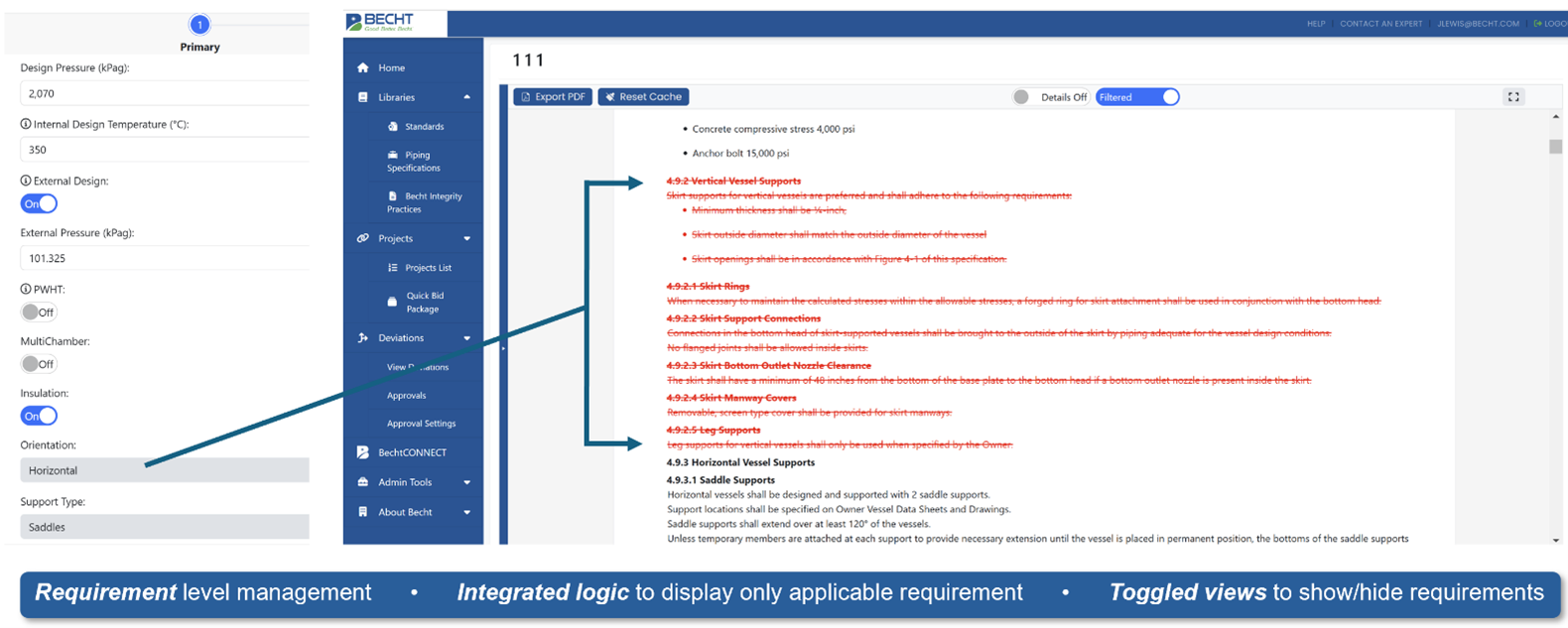

Every feature draws upon Becht’s decades of experience supporting owner-operators in their unique use cases. BechtPractices’ requirements-level organization enables smarter decision-making, faster reviews, and improved compliance. Figure 1 shows how data is organized in an RDMS behind the user-friendly GUI interface and displayed in document-style format, making it easy to adopt and use.

Figure 1: Requirements Database Management System Concept

Smarter Use Through Metadata

Metadata is the engine that drives BechtPractices. Each requirement can include additional information, such as:

- Logic: Defines when and where a requirement applies (i.e., geographical, industry-based, and asset-specific applications using data sheet defined attributes)

- Intent and Interpretation: Offers clarity without changing original meaning or adding bloat to the document

- Associated Information: Captures and highlights other critical information, such as approved exceptions and criticality rating

The platform dynamically filters out non-applicable requirements based on user inputs and corporate defaults, resulting in clean, accurate, and relevant content optimized for every project.

Figure 2 provides an example of content filtering. In this example, pressure vessel design requirements for a vertical vessel are removed since the user is designing a horizontal pressure vessel.

Figure 2: Advanced Filtering in the BechtPractices Portal

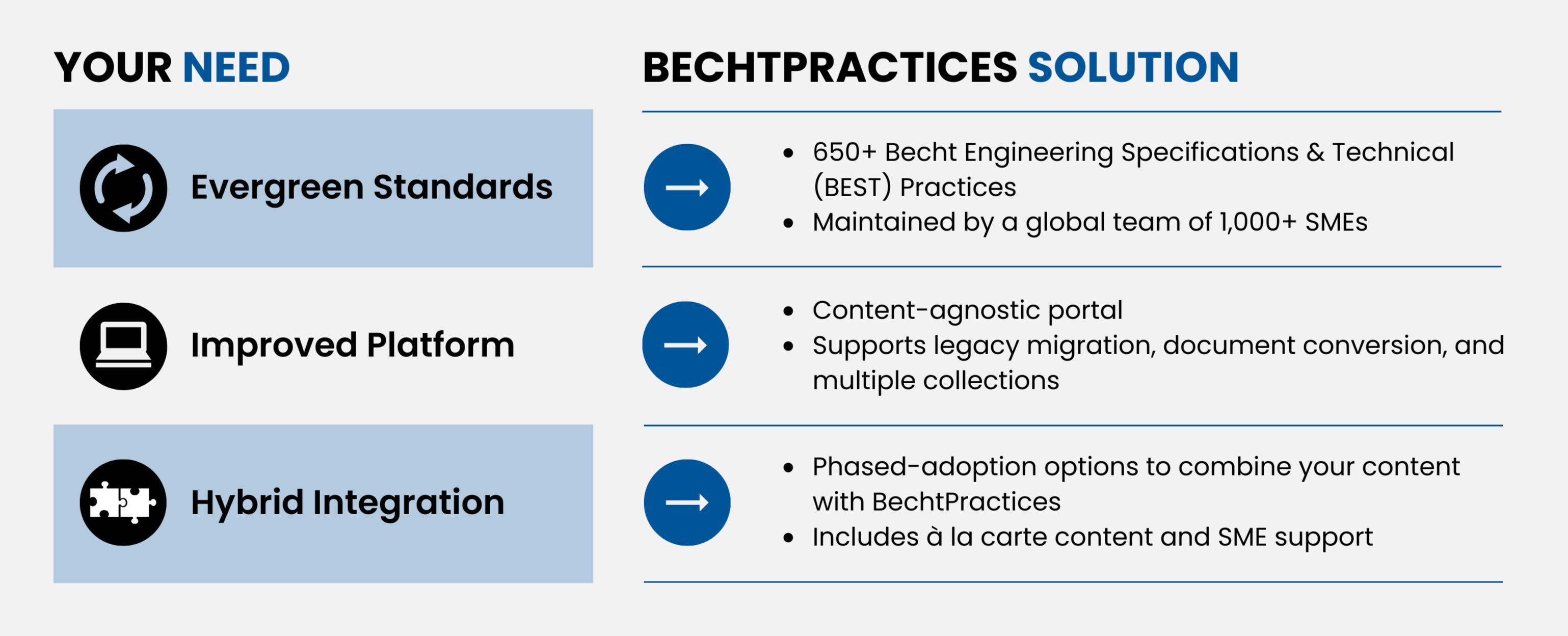

What’s Included with BechtPractices

BechtPractices was built with flexibility, configurability, and integration in mind. Whether you want to adopt our content, migrate your own, or develop a hybrid solution, we’ve got you covered:

What’s Coming in This Blog Series

Here is what to expect in future posts as we dive deeper into the platform’s capabilities. Future articles include:

- Integrated Overlays: Modify general-consensus content (e.g., PIP, IOGP JIP 33) using in-line overlays with toggle views for improved ease-of-use

- Advanced Filtering for Optimized Content

- Logic-based filtering

- Dynamic unit conversions

- Real-time QA checks

- Capital Project Excellence

- Project-specific “locked” collections

- Filtered bid packages

- Improved third-party access

- Expanding Beyond Engineering: How to use the platform to manage other corporate standards, such as:

- Process and mechanical integrity practices

- Maintenance and TAR work procedures

- Improved Content Management

- Integrated and configurable approval workflows

- Historical version comparisons

- Word-like editing in-line backed by a powerful RDMS

- Efficiency Through Industry Integration

- Leverage parallel industry initiatives through Becht’s integration and involvement with organizations and groups such as:

- IOGP’s Capital Facilities Information Handover Specification (CFIHOS)

- Construction Industry Institute’s (CII) Supply Chain Management Community for Business Advancement’s (SCMCBA) Joint Working Group (JWG) to Digitize the Valve Supply Chain

- Leverage Becht’s SME leadership and active involvement in codes and standards committees

- Leverage parallel industry initiatives through Becht’s integration and involvement with organizations and groups such as:

- Conversion and AI Tools

- Automated conversion and migration of legacy Word document services

- AI-powered search and chatbots

- Dashboards for improved analytics and insights

Next Steps

BechtPractices is more than a platform—it’s a modern solution to better manage critical organizational data that helps engineers and managers work smarter and faster.

- Follow us on LinkedIn for upcoming blogs and platform updates.

- Watch the recording of our global webinar, which includes a detailed demo of BechtPractices in action.

- Request a live demo tailored to your organization’s needs by contacting Jeannie Lewis or Matt Hansen.

Let BechtPractices help you unlock better performance, improved compliance, and stronger project execution—starting with how you manage your standards.

Like what you just read? Join our email list for more expert insights and industry updates.